With the advancement of science and technology, many large companies such as Schneider, Ls, and Starline have launched Busway conductor products, with the purpose of helping customers conveniently install power distribution systems. So what is Busway, what advantages does it have over traditional wiring systems. I will find out below this article.

What is Busway?

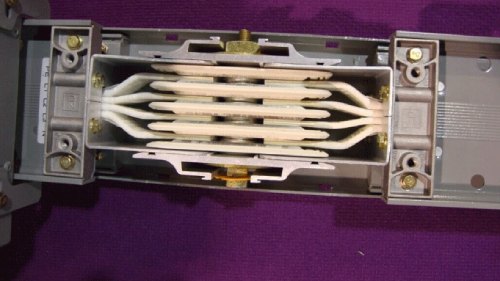

Busway is an electrical conductor system made in the form of rigid sheathed rods, copper core or aluminum core conductors placed in them and covered with special insulating materials, increasing electrical safety compared to using Use traditional wires.

Busway system

The fact is that the Busway guide system is built with a standard size of 3 m and the coupling ends are installed together very flexibly and conveniently.

We are so familiar with traditional electric cables, when manufacturers launched this product line, creating a fever because of its superiority in industrial piezoelectric construction.

Advantages of busway system

In fact, while directly installing this new type of guide rod, we can see the advantages it brings

- Flexibility in transportation and construction. Because busway bars are made to standard sizes, connectors and joints are easy to assemble. We just need to put it in place and connect the accompanying accessories.

- High aesthetics, practical when deployed, the guide bars feel neat in each block, one block at a time, very easy for future monitoring and maintenance

Busway system in industry

- Great electrical conductivity, this is true, as all conductors are made from pure copper bars. Companies have introduced types capable of conducting electricity up to 7000A. Short circuit current resistance is higher than that of conductors.

- Minimize energy loss, because at the joints it is possible to extract electrical conductors from there at a distance of 3m, with low pressure drop. This is different from traditional power cables.

Ability to connect Busway equipment

- Because it doesn't have to be bundled with many wires, it's easy to distinguish and repair.

- Heat dissipation and durability under the influence of force because the shell is machined with metal

- The flexibility of the Bus way system is clearly shown to be easy to disassemble, develop, or revoke the system

- Diverse designs and configurations of diverse busducts to choose from

The product meets IEC60529/ IEC 61439-6/ IP54 standards

Busway electrical conductor structure

Busway guide bar housing

Made from high-quality steel and aluminum with the purpose of reducing delays and losses due to eddy currents when large current flows through. Durable epoxy coating over time

Connector between Busway bars

The guide rod housing is molded directly into the core, sealed with only two joints protruding, with the purpose of protecting the copper core under mechanical and environmental impact.

Busway guide bar

Made from premium copper material with a purity of up to 99.9%, ensuring the best conductivity compared to the designed capacity. The coupling points are bimetallic to ensure rigidity during installation.

All standards are strictly inspected and monitored.

Insulation ability of Busway guide system

Each guide rod is covered with Grade A Polyester insulation film (1300c Du) to ensure absolute safety for humans, avoiding the possibility of electric leakage under environmental impacts.

Made from special materials that should withstand high temperatures for a long period of time, when short circuits occur.

Mounting and support systems

When installing a bus way guide system, you must follow the manufacturer's standards and recommendations.

Hệ thống tổng quan Busway

FEEDER and PLUGIN guides installed indoors maximum distance between mounts = 3M when mounted horizontally, and 5M when mounted vertically .Outdoors is 1.5M for both cases.