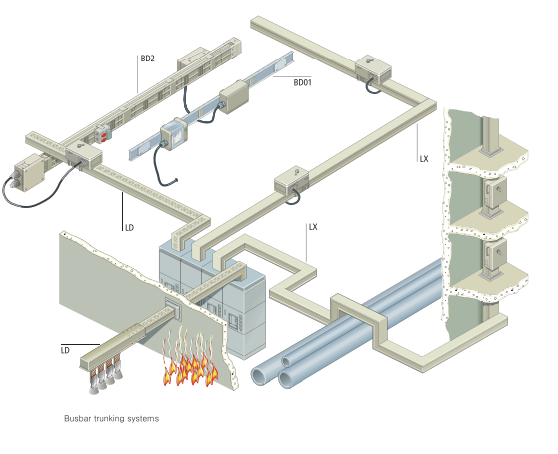

When visiting some high-rise buildings, we can see square bars that conduct electricity between floors. That is the busway system in the building. In this article, we will learn what a busway system is and the structure of a busway system.

Busway system in Siemens building

1. What is a busway system ?

The busway conductor system is a conductive system, used to replace electrical cables, but is made in the form of rigid-sheathed rods and the conductors are converted into copper or aluminum cores, covered with insulating material. The guide bars have a maximum length of 3 m, are connected by connectors, and can have a power location depending on the design and installation location in the building.

The design of a busway system in a building can have many types of axles, but in general there are 3 types as follows:

- Connect from Transformer to main distribution cabinet (LV Panel) (horizontal rise).

- Connect from Generator to main distribution cabinet (LV Panel) (horizontal rise).

- The rod shaft leads from the Distribution Cabinet to the floors (vertical rise).

2. Distinguish between busbar, busway, busduct.

Busbar is a conductive core. Standard conductive core is made from Aluminum or Copper

Busway is defined by NEMA (National Association of Pacific Manufacturers (USA): is a pre-fabricated power distribution system with conductive cores in a protective cover (Bus bar), including bars. basic, connectors, devices, and accessories. Fully: the busway guide system includes conductive cores, insulating materials, housings, and related accessories. Thus, the Busbar is simply a single conductor, while the Busway is composed of many insulated Busbars stacked close together and protected by a shell.

There is a fundamental difference in name and purpose of use:

- Busbars can be located in panel cabinets (with or without protective insulation) and are panel cabinet accessories. When talking about a busbar, it refers to the individual busbar in the electrical cabinet.

- Busbar is a system that replaces cables (or rigid power cables) and is never a panel accessory. Talking about busway is a conductive system that replaces dynamic cables.

- BusDuct is another name for Busway.

3. What are the advantages compared to electric cables of busway systems ?

- Very large electrical conductivity, can be up to 6300A, 7500A - Low loss and capable of extracting electricity from 1 rod shaft at many different locations on the guide rod

- High aesthetics, and saves installation area, saves main power distribution cabinet area.

- Finally, with a certain operating current level (1000A for aluminum core, From 1250A or 1600A or more for copper core), the entire usage cost for busway guide rod system, will be cheaper when using traditional power cable system.

4. Busway guide system manufacturers.

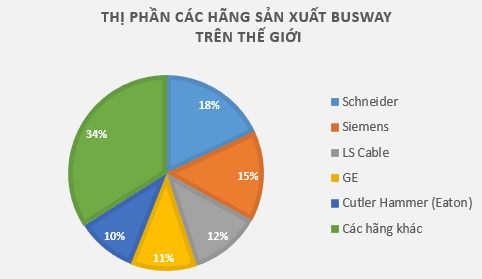

In the world, guide bars began to be commonly used in the 80s in Europe, America, Japan, and Korea. There are hundreds of professional busway guide system manufacturers, but generally only the following are well known and have widely sold products globally:

Market share of busway guide system in the world

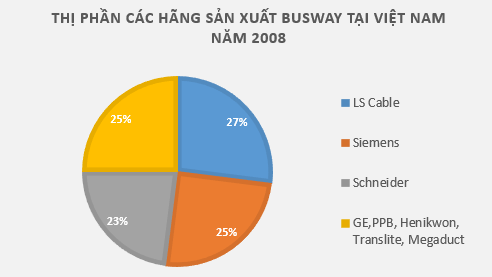

In the Vietnamese market, there are currently 8 main busway guide system suppliers entering Vietnam, and the order of market share in Vietnam in 2008 is as shown in the following chart:

Market share of busway guide system in the Vietnamese market

The most outstanding feature is that global companies (Schneider, Siemens, LS Cable, GE, Eaton) all use aluminum busway guide systems while 3 out of 4 companies from Malaysia (PPB, Henikwon, Translite, Megaduct) use aluminum covers. iron (called metal case).

All global companies have short circuit tests of 1s and 3s at high levels (maximum 150, 200KA). While companies from Malaysia have this test level much lower, some companies even only test 6 Cycles, 3 Cycles (6 cycles - 0.1s, 3 cycles - 0.05s). (Based on the catalog), there are no 1s or 3s tests.

GE/SIEMENS/SCHENIDER companies do not offer to sell Busway manufactured in the US or Europe into Vietnam but offer to sell production from China into Vietnam due to the structure of the companies. These companies made in the US use Epoxy technology, while those made in Asia use Mylar - a type of film produced by Dupont, rolled like tape, and wrapped into the conductive core in the guide bar. Only Schenider still retains Mylar technology in the US, while still producing Epoxy. Maintaining Mylar production in the US to meet buyers' cost-cutting requirements when required.

Thus, the article explains what a busway system is, distinguishes related concepts and introduces some famous manufacturers to readers. Now when visiting a high-rise area, you can suggest seeing more busway systems in the building. The following article will explain in more detail the structure of busway guides.

If you want to learn about BUSWAY - BUSDUCT system, Please Contact Us !